Excavators are critical to many industries in Russia, from construction to mining and forestry. Whether you’re maintaining an existing fleet or expanding your operations, ensuring that you have access to reliable and durable excavator parts is crucial. However, finding the right parts in Russia can be challenging, especially with the vast range of suppliers and products available.

Whether you’re working in construction, mining, or any other industry, investing in the right components will help ensure your operations run efficiently and effectively.

Identify the Specific Excavator Parts You Need

Before diving into the market, it’s crucial to know exactly what you’re after. The world of excavator parts is vast, and not all components are universal. Are you in need of a new hydraulic pump, replacement tracks, or perhaps electrical system components? By identifying your specific needs, you avoid the frustration of sifting through unnecessary options.

Each excavator model has unique specifications. For example, if you own a Hitachi ZX200, the parts will differ from those of a Volvo EC220. Keep your excavator’s make, model, and serial number at your fingertips. This information is your golden ticket to finding the exact match.

Understanding the function of the part helps in making informed decisions. If you’re replacing a crucial component like the hydraulic cylinder, you need to ensure it meets the required pressure ratings and fits seamlessly with your system.

Don’t forget about compatibility with attachments. If you frequently switch between a breaker and a clamshell bucket, make sure the parts you choose accommodate your operational needs. The last thing you want is to invest in excavator components that limit your machine’s versatility.

Knowing precisely what you need not only saves time but also money. It prevents costly mistakes and returns. Plus, suppliers are more likely to offer assistance and accurate quotes when you provide detailed information.

Common Excavator Parts You’ll Need

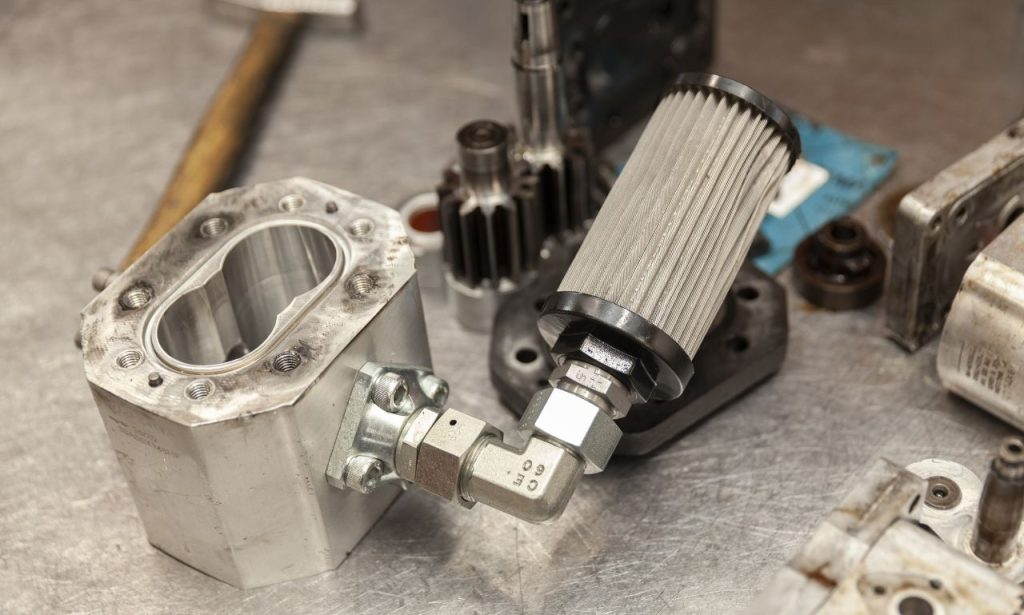

Before diving into where to source parts in Russia, it’s important to understand which components require the most attention in terms of maintenance and replacement. Commonly sought-after excavator parts include:

- Hydraulic Pumps and Motors: Essential for the movement of your machine’s arm and bucket, hydraulic systems must be kept in excellent condition.

- Tracks and Undercarriage Components: The undercarriage supports the entire weight of the machine and is one of the most frequently replaced parts.

- Buckets and Attachments: Different attachments are used for various jobs, making these parts critical for maintaining productivity.

- Booms and Arms: Frequent use leads to wear and tear on these structural parts, requiring periodic replacement.

- Filters and Seals: To keep your machine running smoothly, regular replacement of oil filters, air filters, and seals is necessary.

Where Can You Find Reliable Excavator Parts in Russia?

Finding trustworthy suppliers is paramount. Consider these options for sourcing your excavator parts in Russia:

- Authorized Dealers: These offer genuine parts and warranties, but often come with premium pricing.

- Independent Suppliers: These can offer competitive prices, but due diligence is crucial to verify part authenticity and quality.

- Online Marketplaces: Platforms like Avito and Tiu.ru can connect you with various suppliers, but careful vetting is essential.

- Salvage Yards: A cost-effective option for used parts, but thorough inspection is necessary to ensure usability.

When choosing a supplier, consider their reputation, warranty policies, and delivery timelines. Prioritize suppliers with a proven track record and positive customer reviews. This ensures you receive quality parts and avoid costly downtime.

Where to Source Excavator Parts in Russia

Russia is home to a wide range of suppliers that offer excavator parts, from small independent dealers to large manufacturers. Understanding where to source these components is crucial for both cost and quality.

1. Authorized Dealers

One of the safest ways to ensure you’re getting genuine, high-quality parts is by purchasing through authorized dealers. These suppliers work directly with manufacturers to provide original equipment manufacturer (OEM) parts, which are specifically designed for your machine. While OEM parts might come at a higher price, they offer the reliability and durability you need for heavy-duty tasks.

Popular brands like Caterpillar, Komatsu, and Volvo have authorized dealers across Russia. These dealers not only sell parts but also offer after-sales service, including repairs and maintenance.

2. Online Marketplaces

If you’re looking for more affordable options, online marketplaces like Avito or specialized equipment websites often have a wide selection of new and used excavator parts. These platforms allow you to compare prices from multiple sellers, helping you find competitive deals. However, it’s essential to vet the sellers and ensure that the parts are genuine and in good condition, especially when purchasing used components.

3. Local Manufacturers and Distributors

Russia also has local manufacturers and distributors that produce excavator parts tailored to specific machines and work conditions. These parts are often more affordable than OEM components and may be designed to handle Russia’s unique environmental challenges, such as harsh winters. Many Russian manufacturers focus on producing high-wear items like undercarriage components and hydraulic parts, ensuring they meet or exceed OEM standards.

Local manufacturers can often provide customized solutions for companies that need parts designed for specialized tasks or conditions.

4. Used and Reconditioned Parts

Another option for sourcing excavator parts is through the used and reconditioned market. Many companies in Russia specialize in buying and reconditioning old parts, giving them a second life. This option can save you a significant amount of money compared to buying new parts, but it requires careful selection to ensure you’re getting parts that still have plenty of life left in them.

How Can You Verify the Authenticity of Excavator Parts in Russia?

Counterfeit parts are a significant concern. Protect your investment by verifying authenticity:

- Check Part Numbers: Cross-reference part numbers with the manufacturer’s database to ensure accuracy.

- Inspect Packaging: Genuine parts typically come in high-quality packaging with clear labeling and security features.

- Examine the Part: Look for inconsistencies in casting, machining, or labeling that might indicate a counterfeit.

- Demand Documentation: Request certificates of authenticity or other documentation from the supplier.

Protecting yourself from counterfeit excavator components in Russia requires vigilance and attention to detail. By taking these precautions, you can minimize the risk of purchasing substandard parts.

What are the Challenges of Importing Excavator Parts to Russia?

Importing parts presents logistical and regulatory hurdles:

- Customs Regulations: Familiarize yourself with Russian import regulations and documentation requirements.

- Logistics: Navigating shipping, handling, and customs clearance can be complex and time-consuming.

- Currency Exchange: Fluctuations in currency exchange rates can impact the overall cost of imported parts.

- Lead Times: Factor in potential delays due to shipping and customs processing.

Understanding these challenges allows you to plan accordingly and mitigate potential disruptions to your operations. Proper preparation is key to a smooth import process.

How to Choose the Right Excavator Parts for Your Specific Needs in Russia?

Selecting the correct parts is crucial for optimal performance and longevity:

Consider these factors:

- Machine Model: Ensure compatibility with your specific excavator model and year.

- Application: Choose parts designed for your specific application, whether it’s digging, demolition, or material handling.

- Operating Conditions: Factor in the harsh Russian climate and terrain when selecting parts.

- Budget: Balance cost with quality and longevity to make informed purchasing decisions.

Selecting the right excavator parts in Russia requires a comprehensive understanding of your machine, its application, and the operating environment. Careful consideration of these factors will ensure optimal performance and minimize downtime.

Research Reputable Suppliers in Russia

The supplier you choose plays a huge role in your overall experience. Russia’s market is vast, with a mix of established suppliers and newer entrants. To find trustworthy suppliers, start by conducting thorough research.

Utilize online resources such as industry directories, professional networks like LinkedIn, and trade associations. Suppliers with a strong online presence and professional affiliations are often more reliable.

Don’t hesitate to ask for references. Reputable suppliers will gladly provide contact information for other customers. Speaking directly with these references can offer candid insights into the supplier’s reliability and service quality.

Visiting the supplier’s physical location, if feasible, can also be beneficial. This allows you to assess their operations firsthand. You can see their inventory, meet the staff, and understand their processes.

Another avenue is attending trade shows or industry events in Russia. These events are excellent opportunities to meet multiple suppliers in one place, compare offerings, and establish relationships.

Remember, communication is key. A supplier who responds promptly, provides detailed information, and communicates transparently is more likely to be dependable.

Explore Options for Remanufactured (Reman) Parts

Remanufactured parts are increasingly popular in the construction industry. They’re not just used components; they’re disassembled, cleaned, repaired, and tested to meet or exceed original specs.

Opting for reman parts can significantly save costs—sometimes up to 50% compared to new parts. This is a huge advantage, especially for budget-conscious operations.

When considering remanufactured excavator parts in Russia, verify the reman process used by the supplier. A high-quality remanufacturing process includes complete disassembly, replacement of worn components, and thorough testing.

Ask about the warranty offered on reman parts. A robust warranty indicates the supplier’s confidence in the quality of their remanufactured products. It also provides you with protection and assurance.

Environmental impact is another benefit of choosing reman parts. By reusing components, you’re contributing to sustainability efforts and reducing waste.

However, be cautious of suppliers offering reman parts at prices that seem too good to be true. Extremely low prices may indicate subpar remanufacturing practices or the use of inferior parts.

What are the Key Maintenance Practices for Excavator Parts in Russia?

Proper maintenance extends the lifespan of your excavator parts:

- Regular Inspections: Conduct routine inspections to identify wear and tear or potential issues.

- Lubrication: Proper lubrication is essential for reducing friction and preventing premature wear.

- Fluid Changes: Regularly change fluids, such as engine oil and hydraulic fluid, to maintain optimal performance.

- Cleaning: Keep parts clean to prevent dirt and debris from causing damage.

Adhering to a rigorous maintenance schedule is vital for maximizing the lifespan of your excavator parts in Russia. Regular inspections and preventative maintenance can significantly reduce downtime and costly repairs.

Consider the Quality of Excavator Parts

Quality can’t be compromised when it comes to heavy machinery. Inferior parts can lead to catastrophic failures, endangering safety and causing expensive downtime. When searching for excavator parts in Russia, prioritize quality above all else.

But how do you assess quality? Start by looking for OEM (Original Equipment Manufacturer) parts. These components come directly from the manufacturer and are built to the exact specifications of your excavator. They offer unparalleled reliability and longevity.

If OEM parts are out of your budget, consider high-quality aftermarket parts. Reputable aftermarket suppliers produce components that meet or exceed OEM standards. Ensure that these parts are manufactured using robust materials and have undergone rigorous testing.

Pay attention to the material composition. For instance, parts made from high-grade steel or alloy offer better durability. Corrosion resistance is also important, especially if your excavator operates in harsh environments.

Certifications can also be a quality indicator. ISO certifications or compliance with international standards signify that the manufacturer adheres to stringent quality control processes.

Lastly, don’t overlook the importance of a warranty. Quality excavator parts often come with solid warranties, providing peace of mind and protection against defects.

Understand the Importance of Daily Inspections

Daily inspections are your first line of defense against unexpected breakdowns. They might seem time-consuming, but they save you from costly repairs and downtime.

Start your day with a walk-around inspection: Check for fluid leaks, loose bolts, and signs of wear. Examine the tracks for proper tension and look for any damage to the teeth or bucket.

Inspect the hydraulic hoses and connections: Hydraulic failures can be dangerous and expensive. Early detection of wear or degradation prevents accidents and prolongs the life of your hydraulic system.

Don’t neglect the cab area: Ensure all controls are functioning properly, visibility from the cab is unobstructed, and safety features like seat belts and alarms are operational.

Document any issues you find, no matter how minor: This information is invaluable for maintenance scheduling and part replacement planning.

By making daily inspections a routine, you maintain your excavator’s performance, ensure operator safety, and extend the life of your parts.

Evaluate Maintenance Frequency for Optimal Performance

Maintenance isn’t just about fixing problems—it’s about preventing them. Adhering to a regular maintenance schedule keeps your excavator running at peak efficiency.

Consult your excavator’s manual to determine the recommended maintenance intervals. These schedules are based on hours of operation and are tailored to your machine’s specific needs.

Regular tasks include changing filters, checking and replacing fluids, and inspecting electrical systems. Consistent maintenance reduces the risk of sudden failures and extends the life of critical components.

Consider the operating conditions of your excavator. Harsh environments, like those with extreme temperatures or heavy dust, may require more frequent maintenance.

Implementing a proactive maintenance strategy can also save costs. It’s often less expensive to replace a worn part during scheduled maintenance than to deal with a breakdown in the middle of a project.

Know the Key Components to Focus On

Certain parts of your excavator demand more attention due to their role and the stress they endure.

Relief Valves and Their Impact on Operation

Relief valves are vital for controlling hydraulic pressure. If a relief valve fails, it can lead to excessive pressure, causing damage to the hydraulic system or even catastrophic failure.

Regularly test relief valves to ensure they open at the correct pressure. Replace or repair any valves that show signs of wear or malfunction.

Properly functioning relief valves not only protect your equipment but also enhance performance by ensuring smooth and consistent hydraulic operation.

Undercarriage Parts and Their Significance

The undercarriage supports the entire weight of the excavator and transfers power to the ground. It’s subjected to constant wear and tear.

Key undercarriage components include the tracks, rollers, idlers, and sprockets. Worn tracks can lead to decreased traction and increased fuel consumption. Damaged rollers or idlers can cause uneven wear and affect stability.

Regular cleaning of the undercarriage removes built-up debris that can accelerate wear. Measure track tension and adjust as needed to prevent premature wear.

Investing in high-quality undercarriage parts pays off in the long run. It reduces maintenance costs and prevents downtime.

Essential Attachments for Enhanced Functionality

Attachments transform your excavator into a multi-functional powerhouse. Choosing the right attachments can significantly increase productivity.

Some common attachments include:

- Buckets: Different sizes and shapes for various materials.

- Hydraulic Hammers: For breaking concrete or rock.

- Grapples: Ideal for handling logs or scrap materials.

- Augers: For drilling holes.

Ensure the attachments are compatible with your excavator’s hydraulic system and capacity. Quality attachments reduce wear on the machine and improve efficiency.

Consider renting attachments if you need them for short-term projects. This reduces upfront costs and storage concerns.

Implement Thorough Recordkeeping Practices

Keeping meticulous records is essential for effective equipment management.

Document every maintenance activity, part replacement, and inspection. Include dates, details of the work performed, and any observations.

Use digital tools like maintenance management software to simplify recordkeeping. These tools can send reminders for upcoming maintenance and generate reports.

Accurate records help identify patterns of wear and predict future maintenance needs. They also increase resale value by demonstrating proper care and maintenance.

Utilize Comprehensive Performance Tests to Assess Parts

After installing new parts or conducting repairs, performance tests confirm everything is functioning as it should.

Perform operational tests, such as checking for smooth movement in all hydraulic functions, verifying the accuracy of control inputs, and monitoring engine performance.

Use diagnostic tools to read error codes and assess system health. These tests can detect issues that aren’t visible during a visual inspection.

Regular performance assessments help maintain optimal efficiency and prevent minor issues from escalating.

Compare Prices and Offerings from Multiple Vendors

Price comparison is a smart shopping strategy, even when purchasing excavator parts in Russia.

Reach out to multiple suppliers and request detailed quotes. Ensure you’re comparing like-for-like by providing the same specifications to each supplier.

Look beyond the price tag. Consider factors such as delivery times, warranty terms, and after-sales support.

Be wary of prices that are significantly lower than the market average. This could indicate inferior quality or hidden costs.

Negotiating with suppliers can also yield better deals. Don’t hesitate to discuss price adjustments, especially for bulk orders.

Investigate Customer Reviews and Feedback

Customer feedback is a window into a supplier’s reliability and product quality.

Search for reviews on independent platforms. Pay attention to comments about product quality, customer service, and delivery reliability.

Consider reaching out to past customers directly if possible. They can provide candid insights and answer specific questions you may have.

Remember that no company is perfect. Look for patterns in feedback rather than isolated complaints.

Assess Warranty Options Available for Excavator Parts in Russia

A strong warranty reflects the supplier’s confidence in their products.

Review the warranty terms carefully. Understand what’s covered, the duration of the warranty, and any conditions or limitations.

Some key aspects to look for include:

- Length of Coverage: Longer warranties provide extended protection.

- Scope of Coverage: Does it cover parts, labor, or both?

- Process for Claims: Is the claims process straightforward?

Don’t hesitate to ask the supplier for clarification on any points. A transparent supplier will be open and clear about their warranty policies.

Negotiate Terms with Suppliers for Better Deals

Negotiation isn’t just about price. You can discuss payment terms, delivery schedules, and support services.

Propose payment terms that suit your cash flow, such as net-30 or net-60 terms. Suppliers may be willing to accommodate to secure your business.

Discuss the possibility of bulk discounts if you’re purchasing multiple parts. Long-term relationships can also lead to better terms over time.

Remember to approach negotiations professionally. Building a good rapport with suppliers can lead to mutually beneficial partnerships.

Understand Logistics and Delivery Options in Russia

Russia’s vast geography poses unique logistical challenges.

Work with suppliers who have established distribution networks. They should offer reliable shipping options and provide tracking information.

Consider the location of the supplier relative to your operations. Closer suppliers may offer faster delivery times and lower shipping costs.

Be aware of any regional regulations or restrictions that may affect transportation. Suppliers experienced in dealing with different regions can navigate these challenges effectively.

Factor in delivery times when planning maintenance or repairs. Ordering parts well in advance can prevent project delays.

Consider Local vs. Imported Parts for Availability and Cost

Local parts have the advantage of shorter delivery times and potentially lower shipping costs. They may also be better adapted to local operating conditions.

Imported parts can offer access to a wider range of products, including those from international manufacturers with strong reputations for quality.

However, importing parts may involve additional costs such as customs duties and longer lead times.

Evaluate your priorities. If time is of the essence, local suppliers may be the better option. If you’re seeking specific brands or higher-end products, importing might be worthwhile.

Trust Your Instincts When Selecting a Supplier

Business decisions aren’t solely based on data and analysis. Sometimes, your gut feeling plays a role.

If a supplier seems evasive, unresponsive, or there’s something that doesn’t sit right, consider it a warning sign.

Conversely, if a supplier is proactive, transparent, and communicative, it’s a positive indicator.

Ultimately, you want to work with suppliers who contribute to your success and with whom you can build lasting relationships.

Ready to find top-notch excavator parts in Russia? Take these tips to heart, and gear up for success on your next project.

ALSO READ: What Does AC Maintenance Include

FAQs

Undercarriage components, such as tracks, rollers, and sprockets, are often subject to wear and tear due to the demanding operating conditions. Hydraulic hoses, seals, and filters also require regular

Yes, Russia has regulations regarding the disposal of hazardous waste, which may include certain excavator parts like filters and fluids. Consult local environmental authorities for specific guidelines.

Lead times can vary depending on the supplier, part availability, and shipping location. It’s best to contact suppliers directly for estimated delivery times.

Government incentives and programs can change periodically. Check with relevant government agencies or industry associations for up-to-date information.