You hear a soft tick, barely audible over the engine’s hum. You dismiss it as nothing, a pebble perhaps, flicked up from the road. But deep within the heart of your vehicle, a silent crack is spreading, a hairline fracture in the very foundation of your engine. This is the insidious nature of a cracked cylinder head – a problem that often announces itself only when it’s too late.

Understanding what causes a cracked cylinder head is about more than just car maintenance; it’s about safeguarding your investment and ensuring your safety on the road. This comprehensive guide delves deep into the mechanics, the causes, the symptoms, and the often-costly consequences of this potentially catastrophic engine failure.

Common Causes of a Cracked Cylinder Head

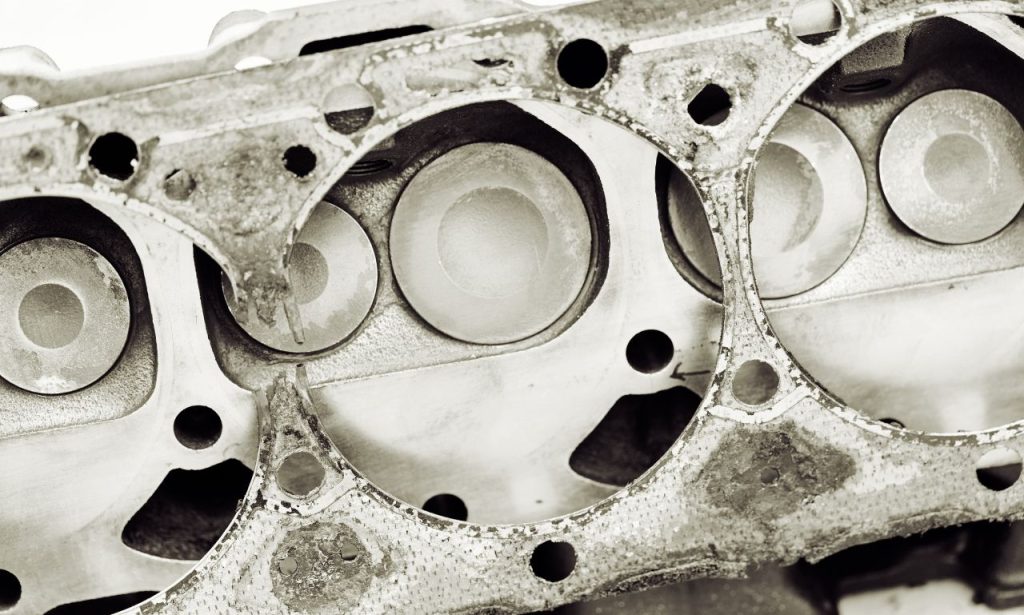

The cylinder head, a critical component of your engine, endures immense pressure and heat. It’s where combustion happens, where fuel ignites, and power is born. But this intense environment also makes it susceptible to a range of issues that can lead to cracks. Let’s explore the most common culprits:

1. Overheating

Imagine your engine as a pressure cooker. As temperatures rise, so does the pressure within the cylinders. Now, picture pouring ice-cold water onto a scorching hot pan – the sudden temperature differential can cause the metal to warp and crack. The same principle applies to your engine.

Overheating is the number one cause of what causes a cracked cylinder head. When your engine overheats, the aluminum alloy of the cylinder head expands rapidly. If the cooling system fails to dissipate this heat effectively, the extreme temperature difference between the hot combustion chamber and the cooler coolant can stress the metal beyond its limits, leading to cracks.

Common reasons for engine overheating include:

- Coolant Leaks: A leaking radiator, hose, or water pump can lead to a loss of coolant, depriving the engine of its vital cooling agent.

- Faulty Thermostat: The thermostat regulates the flow of coolant through the engine. A stuck-closed thermostat prevents coolant circulation, causing rapid overheating.

- Malfunctioning Radiator Fan: The radiator fan draws air through the radiator to cool the coolant. A faulty fan, or one that operates at reduced efficiency, can contribute to overheating, especially during idling or low-speed driving.

- Clogged Radiator: Over time, sediment and debris can accumulate in the radiator, restricting coolant flow and reducing cooling efficiency.

Preventing Overheating:

- Regularly check your coolant levels and look for any signs of leaks.

- Ensure your radiator is clean and free of debris.

- Have your cooling system (including the thermostat, water pump, and radiator fan) inspected and serviced regularly by a qualified mechanic.

2. Material Weaknesses

Not all cylinder heads are created equal. While modern engines typically use robust aluminum alloys, older vehicles might have cast iron cylinder heads, each with its own set of vulnerabilities.

- Aluminum Cylinder Heads: While lighter and better at dissipating heat, aluminum is more susceptible to warping and cracking under extreme thermal stress.

- Cast Iron Cylinder Heads: Though more resistant to cracking from heat, cast iron is prone to cracking due to impacts or if subjected to sudden temperature changes, like pouring cold coolant into an overheated engine.

Beyond the type of metal, several factors can weaken a cylinder head:

- Casting Defects: Imperfections during the manufacturing process can create weak points in the metal, making it more prone to cracking under stress.

- Porosity: Tiny air pockets trapped within the metal during casting can weaken its structural integrity, making it more susceptible to cracking.

- Metal Fatigue: Over time, repeated cycles of heating and cooling, along with the constant pressure changes during combustion, can fatigue the metal, increasing the risk of cracks.

Minimizing Material Weakness Risks:

- Ensure you use the correct coolant type and concentration as recommended by your vehicle manufacturer. Incorrect coolant can corrode the cylinder head, weakening it over time.

- Avoid using stop-leak products as a long-term solution for coolant leaks. These products can clog cooling passages and exacerbate overheating issues.

3. Improper Torque Settings

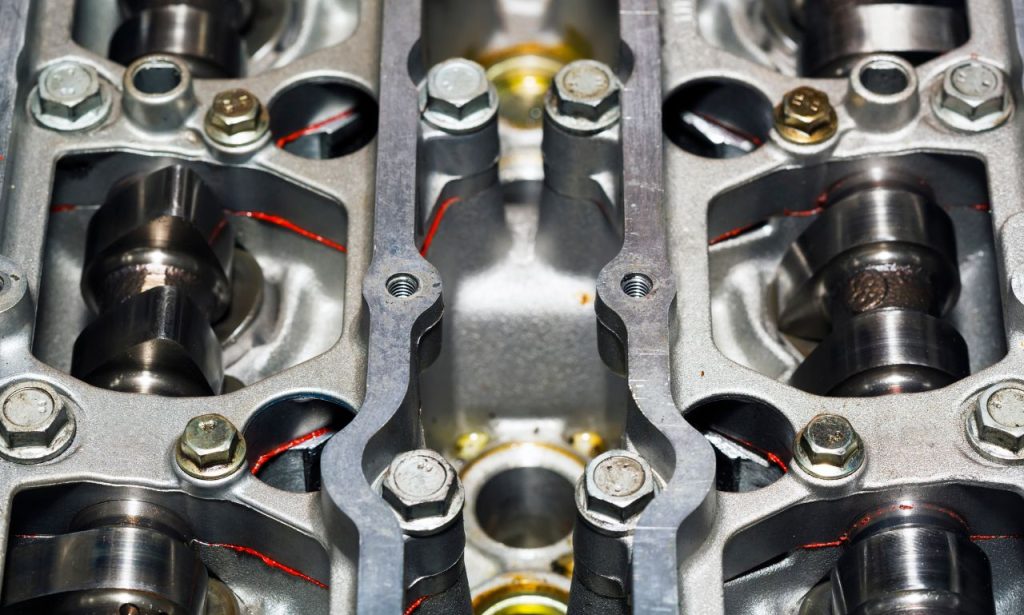

Installing a cylinder head is a precise procedure. The head bolts, responsible for clamping the head to the engine block, need to be tightened to a specific torque specification.

Why is torque so critical?

- Even Pressure Distribution: Proper torque ensures the cylinder head is evenly pressed against the engine block, creating a tight seal that prevents leaks and maintains compression.

- Preventing Warping: Over-tightening the head bolts can warp the cylinder head, while under-tightening can lead to leaks and blown head gaskets, both of which can contribute to overheating and cracking.

The Dangers of Improper Torque:

- Head Gasket Failure: An improperly torqued cylinder head can cause the head gasket to fail, allowing coolant to leak into the combustion chamber or oil passages.

- Cylinder Head Warping: Uneven clamping force can warp the cylinder head, leading to uneven heat distribution and increasing the risk of cracks.

Ensuring Proper Torque:

- Always refer to your vehicle’s service manual for the correct torque specifications and tightening sequence.

- Use a high-quality torque wrench to achieve accurate torque settings.

- If you’re uncomfortable performing this procedure yourself, have a qualified mechanic install the cylinder head.

4. Physical Damage from External Factors

While hidden deep within your engine bay, the cylinder head isn’t immune to external damage.

Here’s what can happen:

- Debris Ingestion: A stray pebble, a loose bolt, or even a small part from a previous repair can be sucked into the engine’s air intake. If this debris makes its way into the combustion chamber, it can strike the cylinder head with enough force to cause a crack.

- Collision Damage: A front-end collision can transmit enough force to the engine to damage the cylinder head, even if there’s no visible external damage to the engine itself.

Protecting Your Engine from External Damage:

- Ensure your engine’s air filter is clean and in good condition. The air filter acts as a barrier, preventing debris from entering the intake.

- Be mindful of road debris and avoid driving through deep puddles or over large objects.

5. Corrosion and Age

Like any metal component exposed to heat, pressure, and the byproducts of combustion, cylinder heads are susceptible to corrosion and wear over time.

How Corrosion Weakens the Cylinder Head:

- Coolant Degradation: Over time, engine coolant can become acidic, corroding the metal of the cylinder head, particularly around the coolant passages.

- Electrolysis: If dissimilar metals are used in the cooling system (for example, an aluminum cylinder head and a copper radiator), electrolysis can occur, leading to accelerated corrosion of the cylinder head.

Combating Corrosion:

- Use high-quality coolant and replace it at the intervals recommended by your vehicle manufacturer.

- Inspect your coolant regularly for signs of discoloration or contamination.

- Consider using a coolant flush product periodically to remove any buildup of rust or scale in the cooling system.

6. Manufacturing Defects

While rare, manufacturing defects can slip through quality control, leading to cylinder heads that are inherently weak or prone to cracking.

Common Manufacturing Defects:

- Casting Flaws: Imperfections during the casting process can create weak points in the metal.

- Improper Heat Treatment: Incorrect heat treatment during manufacturing can alter the metal’s properties, making it more brittle and susceptible to cracking.

Addressing Manufacturing Defects:

- If you suspect a manufacturing defect, contact your vehicle manufacturer. In some cases, they may issue a recall or offer goodwill assistance to address the issue.

Conclusion

Understanding what causes a cracked cylinder head empowers you to take proactive steps to prevent this costly and potentially dangerous engine problem. Regular maintenance, prompt attention to warning signs, and addressing minor issues before they escalate are the best defenses against the silent crack.

Remember, your engine is the heart of your vehicle. Treat it with care, and it will reward you with miles of trouble-free driving.

ALSO READ: What Brand Window Tint Brand is the Best

FAQs

A: It’s not advisable to drive your car with a cracked cylinder head. Doing so can lead to further engine damage, turning a potentially manageable repair into a costly engine replacement.

A: There’s no definitive answer to this question. It depends on the severity of the crack, your driving habits, and other factors. However, driving with a cracked cylinder head is like playing with fire – it’s only a matter of time before something goes wrong.

A: Whether a cracked cylinder head is covered under warranty depends on your vehicle’s warranty terms, the age and mileage of your car, and the cause of the crack. If the crack is deemed to be a result of a manufacturing defect, it might be covered. However, if it’s caused by overheating due to lack of maintenance, it’s unlikely to be covered.